Advantages and Disadvantages of Shell Boilers

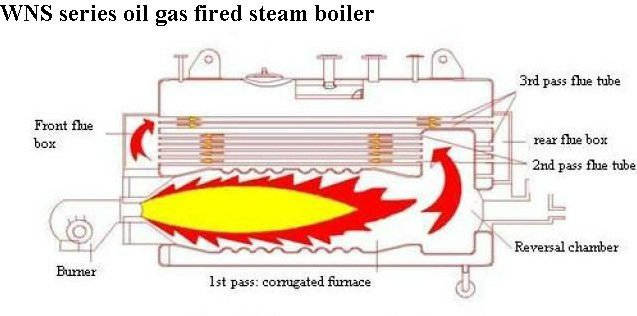

2016-03-09 08:59:02A shell boiler (or called as flued boiler) is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. The shell type boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace.

Advantages of shell boilers:

The entire plant may be purchased as a complete package, only needing securing to basic foundations, and connecting to water, electricity, fuel and steam systems before commissioning. This means that installation costs are minimised.

This package arrangement also means that it is simple to relocate a packaged shell boiler.

A shell boiler contains a substantial amount of water at saturation temperature, and hence has a substantial amount of stored energy which can be called upon to cope with short term, rapidly applied loads.

This can also be a disadvantage in that when the energy in the stored water is used, it may take some time before the reserve is built up again.

The construction of a shell boiler is generally straight forward, which means that maintenance is simple.

Shell boilers often have one furnace tube and burner. This means that control systems are fairly simple.

Although shell boilers may be designed and built to operate up to 1.6MPa, the majority operate at 1.6MPa or less. This relatively low pressure means that the associated ancillary equipment is easily available at competitive prices.

Disadvantages of shell boilers:

The package principle means that approximately 30 ton / h is the maximum output of a shell boiler. If more steam is required, then several boilers need to be connected together.

The large diameter cylinders used in the construction of shell boilers effectively limit their operating pressure to approximately 1.6MPa. If higher pressures are needed, then a water-tube boiler is required.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.