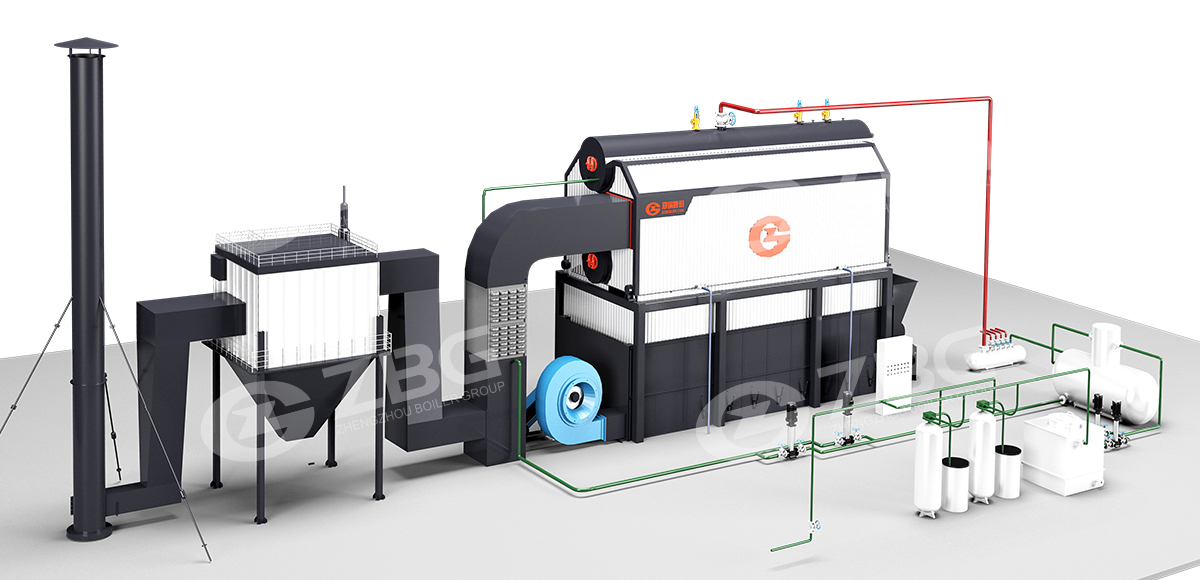

- Capacity : 6-30 t/ 4.2-21 MW

- Pressure ≤1.6MPa

- Biomass Fuel, Rice Husk, Bagasses

Food Industry, Heating Supply

-

Brief introduction:

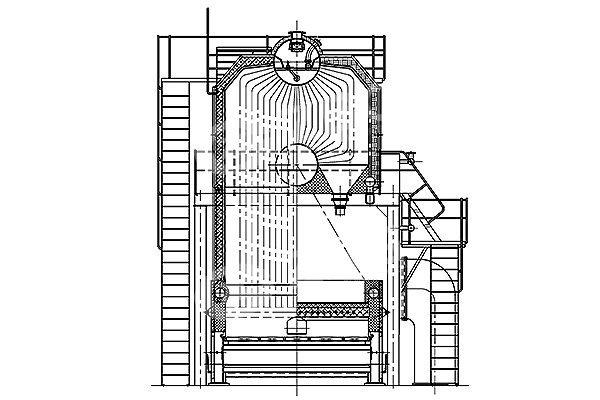

SZL series biomass chain grate boilers with high efficiency, strong overload capacity and various fuel adaptability (biomass pallet or coal), are well known as the best design among contemporary domestic similar products and have reached the world's advanced level. The boiler is mainly composed of upper and lower drums, convection tubes, water-cooling wall tubes, down pipes and headers.

-

Membrane water cooling wall structure

By adopting the water-cooling system in packaged boilers which is usually used in power plant boilers, the boiler can achieve large heat transfer area, high heat transfer efficiency, low heat loss, good air tightness, and no distortion or dust leakage of the brickwork.

-

-

Inverted α furnace arch design

a.Longer fuel combustion period. Front arch is higher and shorter than rear arch, 45°angle between the two arches, which can extend the time of flue gas combustion time, and enhance thermal transferring efficiency.

b.Available to burn various biomass. It design can burn biomass fuels such as rice husk, wood, bagasse, straw, sawdust, sunflower shells, as well as low calorific value coal.

-

Burning effect is good

Wind is feed from both sides of the boiler. There are six independent air chambers, each of them has independent air adjustment device which can respectively adjust the air volume so as to achieve the best combustion effect.

- Long grate, strong overload capacity

The distance between the front shaft and the rear shaft of the grate stoker is longer than other similar type products. In this way, the combustion time of the fuel in the furnace is extended and the fuel combustion is more sufficient and the carbon content in the slag is decreased. Meanwhile, the actual heating surface of the grate is increased and the overload capacity is remarkably enhanced.