- Capacity : 2-35 t/1.4-24.5 MW

- Pressure ≤2.5MPa

- Sinter machine flue gas

Iron & steel industry

-

Brief introduction:

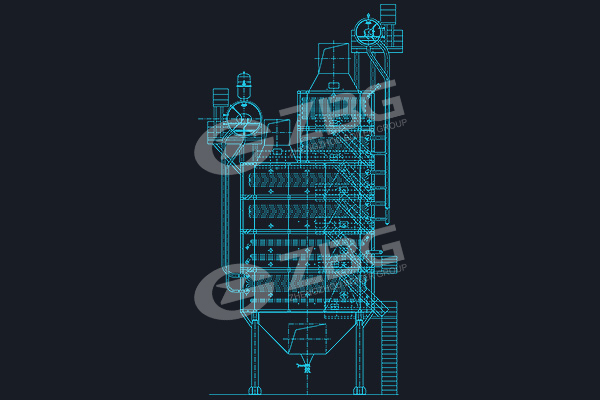

Sinter-cooler waste heat boiler is available to sinter-cooler machine in iron & steel industry. The vertical waste heat recovery boiler (WHRB) successfully solves the ash fouling, abrasion, leakage and other problems, reduces sinter process energy consumption, realize energy saving and finally lower the product unit price.

-

Hot gas grade improved

The temperature distribution of the hot exhaust gas of the conventional sinter cooling device is wide (150 ℃ ~ 450 ℃), which brings great difficulties for the waste heat recovery. The reverse heat transfer of the sinter cooler produced by the Company makes the temperature of the hot exhaust gas stable and comprehensively improves the quality of the recovered sintered heat, while keeping the hot exhaust gas temperature of all the coolers at 450 ~ 550 ℃, which is about 150 ° C higher than the temperature of the conventional cooler outlet hot exhaust gas.

-

-

Enhance dust-collection efficiency, low pollution

Inertial Separation Principle realizes gas solid separation in boiler which has overcome the defects of low efficiency of soot cleaning, heavy environmental pollution and natural soot subsidence for traditional boiler.

-

Cooling equipment leakage rate is greatly reduced

Conventional sintering cooling device leakage rate is as high as 40% to 50%, the larger air leakage rate makes the power consumption of the fan increase, sinter permeability is poor. The sintering cooler of our company adopts a closed chamber to cool the sintering, good air tightness so that the leakage rate close to zero.