CHP Paper Mill Power Plant Waste Heat Recovery Kazakhstan

2016-08-01 17:25:02Waste heat recovery is combined heat and power’s sister technology. Like combined heat and power, it turns excess heat into clean electricity and useful steam. The difference is that it captures the waste heat a manufacturer is already emitting rather than providing all of the energy from scratch. A Kazakhstan paper mill built a waste heat boiler and utilized its waste heat for power generation.

Combined Heat and Power/CHP in paper mill

As I mentioned above, the waste heat recovery is the sister technology of CHP, here let’s have a further understanding of CHP. Cogeneration (cogen) through combined heat and power (CHP) is the simultaneous production of electricity with the recovery and utilisation heat. Cogeneration is a highly efficient form of energy conversion and it can achieve primary energy savings of approximately 40% by compared to the separate purchase of electricity from the national electricity grid and a gas boiler for onsite heating. Combined heat and power plants are typically embedded close to the end user and therefore help reduce transportation and distribution losses, improving the overall performance of the electricity transmission and distribution network (see district energy for more details). For power users where security of supply is an important factor for their selection of power production equipment and gas is abundant, gas-based cogeneration systems are ideally suited as captive power plants.

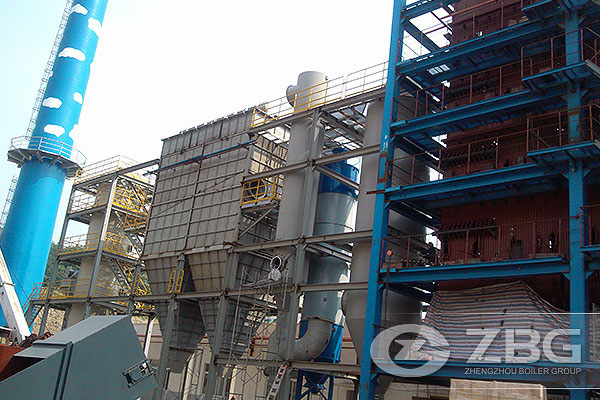

Waste heat recovery boiler for CHP power plant

ZBG has rich experience in waste heat boiler designing and manufacturing, we supply the boilers for CHP, cogeneration for paper mill, chemical industry, cement plant, glass industry for Kazakhstan, Mexico, China, Korea, Japan, America, Vietnam, etc.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.