Difference Between Waste Heat Boiler and Ordinary Industrial Boiler

2021-08-24 15:49:09At present, a large amount of domestic waste heat resources are emptied, which not only causes energy waste but also pollutes the environment. Therefore, the promotion of waste heat recovery, recycling and energy saving will effectively promote the realization of the goal of "carbon neutrality".

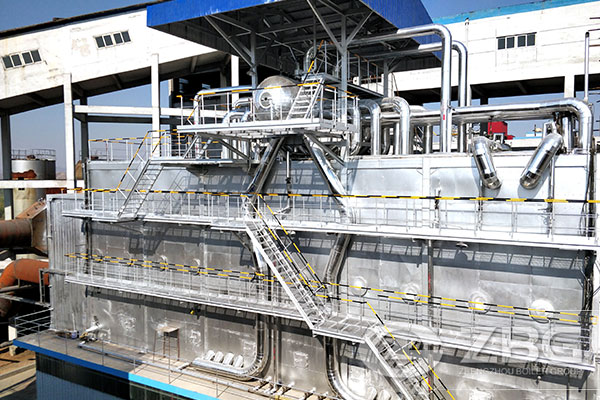

ZBG Boiler Group, as a professional manufacturer of waste heat boilers, will show you the differences between waste heat boilers and ordinary industrial boilers.

1. The difference in structure. Ordinary industrial boilers have complex structures and many auxiliary equipment, which are generally composed of furnaces, drums, burners, water walls, super heaters, economizers, air preheaters, frames, and furnace walls; while waste heat boilers have simple structures. It is usually straight-through, consisting of economizer, evaporator, super heater, header and steam drum and other heat exchange tube groups and containers.

2. The difference in fuel. Ordinary industrial boilers burn natural gas, diesel, petroleum, biomass, coal and other fuels to produce steam and hot water for production; while waste heat boilers use existing waste heat from exhaust gas or solid sensible heat. Due to the high extinguishing temperature of ordinary industrial boilers, the waste heat of exhaust gas is used again by the waste heat boiler.

3. The difference in pressure range. Generally speaking, production requires relatively stable steam and hot water temperature, so there is a fixed pressure value for a relatively period of time. The waste heat boiler can generate steam in a multi-pressure state to improve heat recovery efficiency.

4. The difference between fuel combustion devices. Unlike ordinary industrial boilers, waste heat boilers do not need to burn fuel, so waste heat boilers do not have fuel burning devices.

5. The difference with the main process relationship. Ordinary industrial boilers are generally important equipment in the main process operation program, and the waste heat boiler as the waste heat utilization must be adapted to the needs of the main process and cannot affect the operation of the main process.

6. The difference in the layout of the heating surface. The structure of ordinary industrial boilers is relatively uniform, and all changes are inseparable from those types of scopes. The design and manufacture of waste heat boilers are affected by the flue gas side parameters, boiler parameters, the industry of the main flue gas system, system process descriptions, and meteorological parameters of the boiler installation site. The layout of the heating surface is diversified.

Want to know more details about waste heat recovery boilers? Welcome to consult online customer service, or directly call +86 177 1999 3430, ZBG Boiler Group will serve you wholeheartedly!

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.