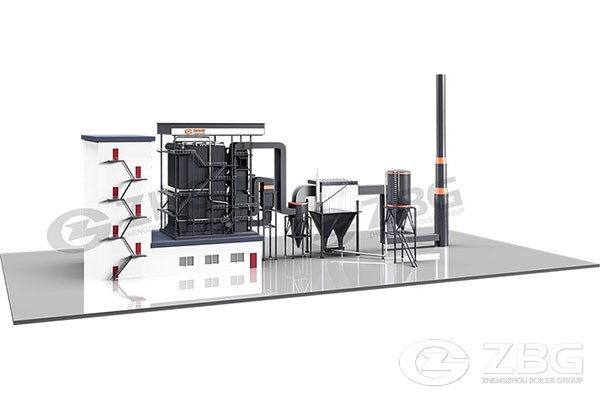

4MW BioMass Power Plant Boiler

2022-10-20 09:20:004MW BioMass Power Plant Boiler

- Plant location : St Thomas, Jamaica

- Nearest airport : 70 miles

- METEOROLOGY

- Wet bulb temperature : +27°C

- Ambient temperature : 40°C (For performance)

- Relative Humidity : 60% (For performance)

- WIND / SEISMIC DATA

- Basic Wind speed : 30 m/s

- Area Classification : Safe & Non – hazardous

Non- Corrosive

- Elevation of site above MSL : 100 m

- Seismic Zone : Zone 3

- Wind direction : Customer to provide

FUEL FOR LOAD CARRYING

- 100% Bagasse 100% MCR

- Or 100% LNG MCR

- Or part Bagasse and part LNG MCR

FUEL ANALYSIS (% BY WEIGHT AS FIRED BASIS)

Ultimate Analysis Bagasse

- Carbon 22.29

- Hydrogen 03.08

- Sulphur 00.00

- Oxygen 20.63

- Nitrogen 00.00

- Moisture 52.00

- Ash 02.00

- Chlorine 0.00

Gross Calorific Value - Kcal/kg 2146

4MW BioMass Power Plant Boiler

FUEL SIZE

Bagasse Milled Bagasse

LNG gas

SOURCE OF WATER: RIVER

SL .NO TESTS UNIT VALUES

1. PH at 25 Deg.C 7-8

2. Temperature Deg C -

3. Dissolved O2 mg/l -

4. BOD mg/l -

5. COD mg/l 5

6. TSS mg/l -

7. Bi- Carbonate (HCO3 ) mg/l 50-120

8. Sulphate ( as So4) mg/l 20

9. Total Hardness as CaCo3 mg/l <5

10. Total alkalinity as CaCo3 mg/l 100

BAGASSE FIRED BOILER SUITABLE FOR THE FOLLOWING WORKING CONDITIONS:

MCR Evaporation of boiler (Gross) kg / hr

Superheated steam pressure at main

steam stop valve outlet

Bar (a) 45

Superheated steam temperature at main

steam stop valve outlet

°C 420 +/- 5

Superheated steam temperature control

range (during Bagasse Firing )

% BMCR 60 – 100 for Bagasse firing

PARAMETERS UNIT VALUE

Feed Water temperature at deaerator

outlet / economiser inlet

°C 105

Flue gas temperature leaving air heater

during 100% bagasse firing

°C 150

No. of Boilers Nos One

STEAM TURBINE Back pressure

Number of Turbine Nos. 1

Type of Turbine

Multistage, Backpressure Steam

turbine

Rated Capacity MW 4 (Gross)

Turbine inlet flow TPH

Superheated steam Pressure at Turbine

Inlet

Bar (a) 42

Superheated steam temperature at

Turbine inlet

°C 415

Min. safe continuous load permissible % 30

Type of Cooling & Type of Condenser

Not applicable

During off season –Dump

condenser is considered

Turbine exhaust flow TPH Process steam +Deaerator

PARAMETERS UNIT VALUE

heating steam

Process steam flow during season shall be TPH

Process condensate return shall be 90%@90°C

Makeup water temperature 25°C

Exhaust Pressure Bar (a) 3.00

Feed water Heaters (except Deaerator) Not applicable

DUMP CONDENSER During off season Only

Tube MOC SA 249 TP 304 ERW

Plugging margin 5

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.