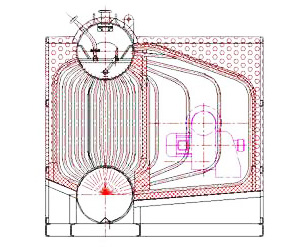

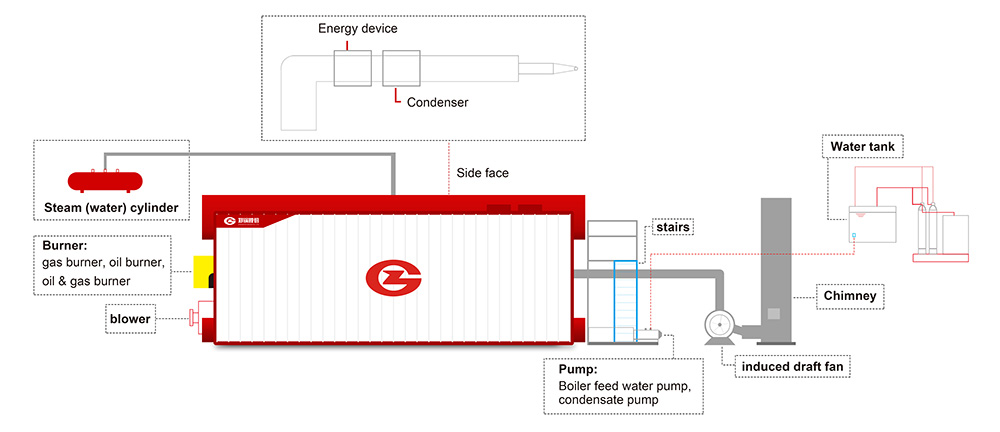

The SZS is a typical D-type water tube boiler design, Bi-drum packaged gas & oil fired boiler. It is mainly composed by upper-drum (steam drum ) & lower-drum(water drum), membrane water cooling wall, convection bank, economizer, and condenser. Burner is arranged in the front wall, after fuel combustion in the furnace, flue gases flow through convection bank, economizer, condenser, and finally discharge into the chimney.

The boiler has a D-type, double drums and a longitudinal layout. Compact structure, the important components (like drums) are not directly affected by the high temperature flame radiation and erosion, to ensure safe and reliable operation of the boiler.

| Items ↓ | Models → | SZS6-1.25-Y.Q | SZS10-1.25-Y.Q | SZS15-1.25-Y.Q | SZS20-1.25-Y.Q | SZS25-1.25-Y.Q | SZS30-1.25-Y.Q | SZS35-1.25-Y.Q |

| Items ↓ | Models → | SZS6-1.25-Y.Q | SZS10-1.25-Y.Q | SZS15-1.25-Y.Q | SZS20-1.25-Y.Q | SZS25-1.25-Y.Q | SZS30-1.25-Y.Q | SZS35-1.25-Y.Q | |

| Rated Capacity | t/h | 6 | 10 | 15 | 20 | 25 | 30 | 35 | |

| Rated Steam Pressure | MPa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Rated Steam Temperature | ℃ | 194 | |||||||

| Feedwater Temperature | ℃ | 104 | |||||||

| Designed Thermal Efficiency | % | 93 | 93 | 94 | 94 | 94 | 94 | 92 | |

| Flue Gas Temperature | ℃ | 145 | |||||||

| Combustion Way | Chamber Combustion | ||||||||

| Combustion Adjustment Way | Electric Control Cabinet Automatic Adjustment | ||||||||

| Fuel Consumption | Light Diesel Oil | kg/h | 360 | 640 | 960 | 1300 | 1600 | 1950 | 2250 |

| Natural Gas | Nm³/h | 450 | 750 | 1100 | 1450 | 1870 | 2200 | 1625 | |

| City Gas | 910 | 1540 | 2260 | 2980 | 3705 | 4400 | 5135 | ||

| Coke Oven Gas | 840 | 1400 | 2100 | 2800 | 3500 | 4200 | 4900 | ||

| Methanol | kg/h | 844 | 1410 | 2120 | 2815 | 3530 | 4240 | 4890 | |

| Max Shipping Weight | t | 26 | 37 | 44 | 55 | 58 | 60 | 64 | |

| Max Shipping Size | mm | 5980*3035*3320 | 7200*3280*3307 | 9000*3280*3307 | 9280*3600*3618 | 10850*3640*3930 | 10450*3890*4210 | 12370*4280*4210 | |

| Max Dimension After Installation | mm | 8320*5500*4260 | 8500*5865*4670 | 9500*5865*4670 | 12220*6850*4495 | 13620*6390*4820 | 13220*7230*4895 | 15140*7920*4765 | |

| Smoke Interface Dimension | mm | 800*490 | 1200*700 | 1000*1000 | 1400*1100 | 1400*1100 | 1400*1100 | 1700*1030 | |

| Interface Dimensions | Feedwater | mm | DN50 | DN50 | DN50 | DN80 | DN80 | DN80 | DN80 |

| Main Steam | DN125 | DN150 | DN150 | DN200 | DN200 | DN200 | DN250 | ||

| Periodic Blow Down | DN25 | ||||||||

| Continuous Blowdown | DN25 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | ||

| Safety Valves | DN80+DN50 | DN80+DN80 | DN100+DN100 | DN100+DN100 | DN100+DN100 | DN150+DN150 | DN150+DN150 | ||

| Feedwater Pump Electric Power | kw | 7.5 | 11 | 18.5 | 22 | 30 | 45 | 55 | |

| Draught Fan Electric Power | kw | Depends On The Burner | |||||||

| Note: | 1. All of these values are calculated by the standard of LNG Qdw=8,400kcal/Nm³,CG Qdw=4,000kcal/Nm³, Coke Oven Gas Qdw=4,200kcal/Nm³, Light Diesel Oil Qdw=10,200kcal/kg, Methanol Qdw=4650Kcal/K. | ||||||||

| Items ↓ | Models → | SZS6-1.25/ 350-Y.Q |

SZS10-1.25/ 350-Y.Q |

SSZS15-1.25/ 350-Y.Q |

SZS20-1.25/ 350-Y.Q |

SZS25-1.25/ 350-Y.Q |

SZS30-1.25- Y.Q |

SZS30-1.25/ 350-Y.Q |

| Items ↓ | Models → | SZS6-1.25/ 350-Y.Q |

SZS10-1.25/ 350-Y.Q |

SSZS15-1.25/ 350-Y.Q |

SZS20-1.25/ 350-Y.Q |

SZS25-1.25/ 350-Y.Q |

SZS30-1.25- Y.Q |

SZS30-1.25/ 350-Y.Q |

|

| Rated Capacity | t/h | 6 | 10 | 15 | 20 | 25 | 30 | 35 | |

| Rated Steam Pressure | MPa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Rated Steam Temperature | ℃ | 350 | |||||||

| Feedwater Temperature | ℃ | 104 | |||||||

| Designed Thermal Efficiency | % | 93 | 93 | 94 | 94 | 94 | 94 | 94 | |

| Flue Gas Temperature | ℃ | 145 | |||||||

| Combustion Way | Chamber Combustion | ||||||||

| Combustion Adjustment Way | Electric Control Cabinet Automatic Adjustment | ||||||||

| Fuel Consumption | Light Diesel Oil | kg/h | 396 | 715 | 1080 | 1490 | 1890 | 2250 | 2610 |

| Natural Gas | Nm³/h | 515 | 827 | 1240 | 1714 | 2142 | 2571 | 3002 | |

| City Gas | 1006 | 1703 | 2498 | 3294 | 4093 | 4886 | 5656 | ||

| Coke Oven Gas | 924 | 1540 | 2310 | 3080 | 3850 | 4620 | 5418 | ||

| Methanol | kg/h | 934 | 1563 | 2345 | 3105 | 3899 | 4961 | 5403 | |

| Max Shipping Weight | t | 27 | 29 | 46 | 26 | 60 | 64 | 64 | |

| Max Shipping Size | mm | 5980*3035*3320 | 7200*3280*3307 | 9000*3280*3307 | 9280*3600*3618 | 10850*3640*3930 | 10450*3890*4210 | 12370*4280*4210 | |

| Max Dimension After Installation | mm | 8320*5500*4260 | 8500*5865*4670 | 9500*5865*4670 | 12220*6850*4495 | 13620*6390*4820 | 13220*7230*4895 | 15140*7920*4765 | |

| Smoke Interface Dimension | mm | 800*490 | 1200*700 | 1000*1000 | 1400*1100 | 1400*1100 | 1400*1100 | 1700*1030 | |

| Interface Dimensions | Feedwater | mm | DN50 | DN50 | DN50 | DN80 | DN80 | DN80 | DN80 |

| Main Steam | DN125 | DN150 | DN150 | DN200 | DN200 | DN200 | DN250 | ||

| Periodic Blow Down | DN25 | ||||||||

| Continuous Blowdown | DN25 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | ||

| Safety Valves | DN80+DN50 | DN80+DN80 | DN100+DN100 | DN100+DN100 | DN100+DN100 | DN150+DN150 | DN150+DN150 | ||

| Feedwater Pump Electric Power | kw | 7.5 | 11 | 18.5 | 22 | 30 | 45 | 55 | |

| Draught Fan Electric Power | kw | Depends On The Burner | |||||||

| Note: | 1. All of these values are calculated by the standard of LNG Qdw=8,400kcal/Nm³,CG Qdw=4,000kcal/Nm³, Coke Oven Gas Qdw=4,200kcal/Nm³, Light Diesel Oil Qdw=10,200kcal/kg, Methanol Qdw=4650Kcal/K. | ||||||||

| Items ↓ | Models → | SZS17.5-1.6/130/70-Y、Q | SZS58-1.6/130/70-Y、Q |

| Items ↓ | Models → | SZS17.5-1.6/130/70-Y、Q | SZS58-1.6/130/70-Y、Q | |

| Rated Thermal Power | mw | 17.5 | 58 | |

| Rated Outlet Water Pressure | MPa | 1.6 | 1.6 | |

| Rated Outlet Water Temperature | ℃ | 130 | 130 | |

| Rated Inlet Water Temperature | ℃ | 70 | 70 | |

| Desighed Thermal Efficiency | % | 94 | 94 | |

| Flue Gas Temperature | ℃ | 110 | 120 | |

| Combustion Way | Chamber Combustion | Chamber Combustion | ||

| Combustion Adjustment Way | Electric Control Cabinet Automatic Adjustment | |||

| Fuel Consumption | Light Diesel Oil | kg/h | 1600 | 4850 |

| Natural Gas | Nm³/h | 1950 | 5680 | |

| City Gas | 3710 | 13500 | ||

| Coke Oven Gas | 3508 | 12500 | ||

| Methanol | kg/h | 3539 | 11290 | |

| Max Shipping Weight | t | 53 | Field Assembled | |

| Max Shipping Size | mm | 10850*3640*3930 | Field Assembled | |

| Max Dimension After Installation | mm | 14100*8050*4400 | Field Assembled | |

| Smoke Interface Dimension | mm | 1400*1100 | 2560*806 | |

| Interface Dimensions | Feedwater | mm | DN300 | DN400 |

| Main Steam | DN300 | DN400 | ||

| Continuous Blowdown | DN20 | DN50 | ||

| Safety Valves | DN100 | DN200+DN200 | ||

| Draught Fan Electric Power | kw | Depends On The Burner | Depends On The Burner | |

| Note: | 1. All of these values are calculated by the standard of LNG Qdw=8,400kcal/Nm³,CG Qdw=4,000kcal/Nm³, Coke Oven Gas Qdw=4,200kcal/Nm³, Light Diesel Oil Qdw=10,200kcal/kg, Methanol Qdw=4650Kcal/K. | |||

CASE 110 ton water tube gas fired boiler

Project: SZS10-1.25-Y.Q 10 ton gas fired steam boiler

Application area: metallurgical plant

Project site: Gongyi, Henan

Client Comment: The gas fired boiler operates well, and consumes less fuel than we expected, it has saved us large running cost.

CASE 214 MW Gas Oil Hot Water Boiler

Project: WNS14-1.0/95/70-Q gas hot water boiler

Application area: heating supply

Project site: Beijing, China

Client comment: we asked ZG Group designed this boiler for our paper plant to burn the coal gas which has low heat value.

CASE 317.5MW gas fired hot water boiler

Project: SZS17.5-1.0/95/70-Q gas fired boiler for heating supply

Application: heating supply

Project site: Jianghan Oilfield, Hubei

Client comment: After comparing the boiler companies we have visited, we decide to purchase the hot water boiler from ZG Group.

Established in 1945, the 70-year-old ZG Group has rich experience in boiler designing, manufacturing, marketing, installation, and maintenance.

B/ State-of-the-art equipment

B/ State-of-the-art equipment

1600mm panel bending machine

120mm CNC bending machine

Fully automatic coiler generating line

20x5x5.5 CNC annealing furnace

Membrane water cooling wall production line

Adhering to technology innovation as the driving force and independent intellectual property rights as the core, ZG Group has built professional R & D team, introducing international advanced technology from America, Germany and other countries, establishing long-term cooperation with Chinese Academy.

ZG Group is always ready to provide you with online product consultation, customer-designed solution, and technical support.

Field installation guide and training will be provided by experienced engineers; they guide boiler installation, solve the problems occurred during the process as well, to ensure the installation process. Adequate consumable parts are freely provided, in case of their wear-and-abrasion affecting product’s efficient running.

Feel free to Contact Us via Online Customer Service, Telephone, E-mail, to get whatever you want.

1、Online Customer Service Live Chat

2、Email: zbg@zzboiler.com

3、Skype: 17719993430

4、Telephone: 0086-371-86062323

5、Factory Address: NO.88 Science Road, High and New Technology

Development District, Zhengzhou, China

The form below with * are required, please fill in your detailed requirements,for example: Evaporation capacity, Outlet steam pressure, Outlet steam temperature, etc..