- Mode:

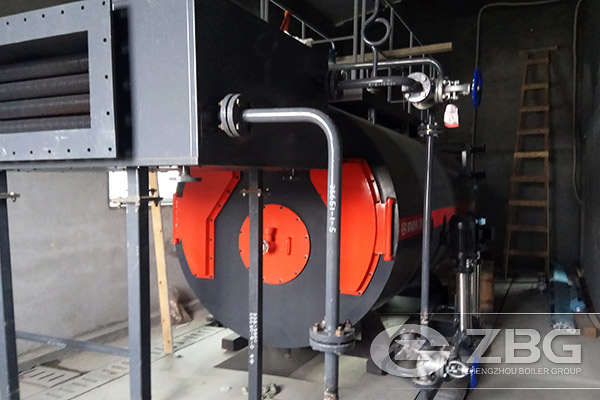

WNS3-1.25-Y/Q

- Capacity:

3 tons

- Application:

Building materials industry

The Customer purchase this 3 tons gas boiler for concrete mixing station project. At present, the equipment has been in normal operation, and customers are very satisfied with our boiler.

After concrete pouring, if the climate is hot and the air is dry, and the maintenance is not carried out in time, the water in concrete will evaporate too quickly, and dehydration will occur, which will make the cement particles that have formed gel body not fully hydrated. In addition, when concrete does not have enough strength, premature evaporation of water will produce larger shrinkage deformation and dry shrinkage cracks. So it is very important to maintain the concrete in the initial stage after pouring, and the steam boiler is the most critical equipment for the steam maintenance of concrete.

WNS series oil and gas fired boiler produced by our company is one of the key export products of our company, can be widely used in production, power generation, heating, hot water supply and other fields. The measured NOx emission concentration is far below 30mg/m3.

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.