Capacity:10-160 tons

Corner tube power plant boiler adopts GEF program's technology. Based on the domestic and foreign technical research, according to the technical development characteristics and market demand of chain grate, we carried out independent innovative design so as to produce the high-capacity energy-saving chain grate boilers with advantages of reliable water cycling, efficient burning and low pollution.

Corner tube type and self load bearing structure to solve the problems of expansion and support;

Full welding membrane water wall structure, good sealing, small heat loss;

Adopt cross beam type grate, the operation resistance is small, the failure rate is low;

layer combustion + suspension combustion", high efficiency.

Capacity:35-410 tons

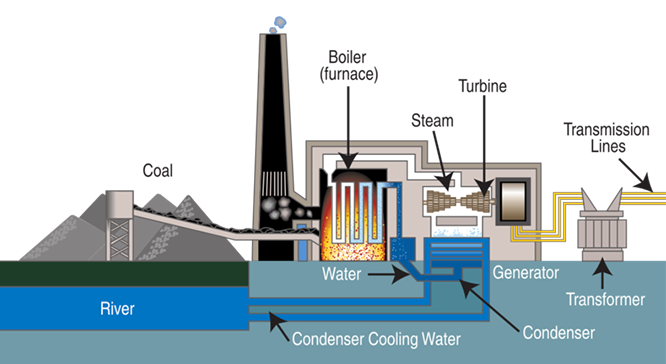

Circulating fluidized bed boiler is the heat equipment used mainly in the western development, using this technology can make S02 and N0x coal-fired power plant boiler flue gas concentration of harmful gas is reduced by 80% ~ 90%, can effectively reduce coal-fired power generation for the atmospheric pollution of the environment.

Furnace and secondary air: make combustible materials burn out in the furnace;

superheater: avoid high temperature superheater ash deposition, reduce the high temperature corrosion;

Low pressure operation, low flow speed of flue gas, low density of materials in the furnace;

Annual operating time longer than 8000 hours.